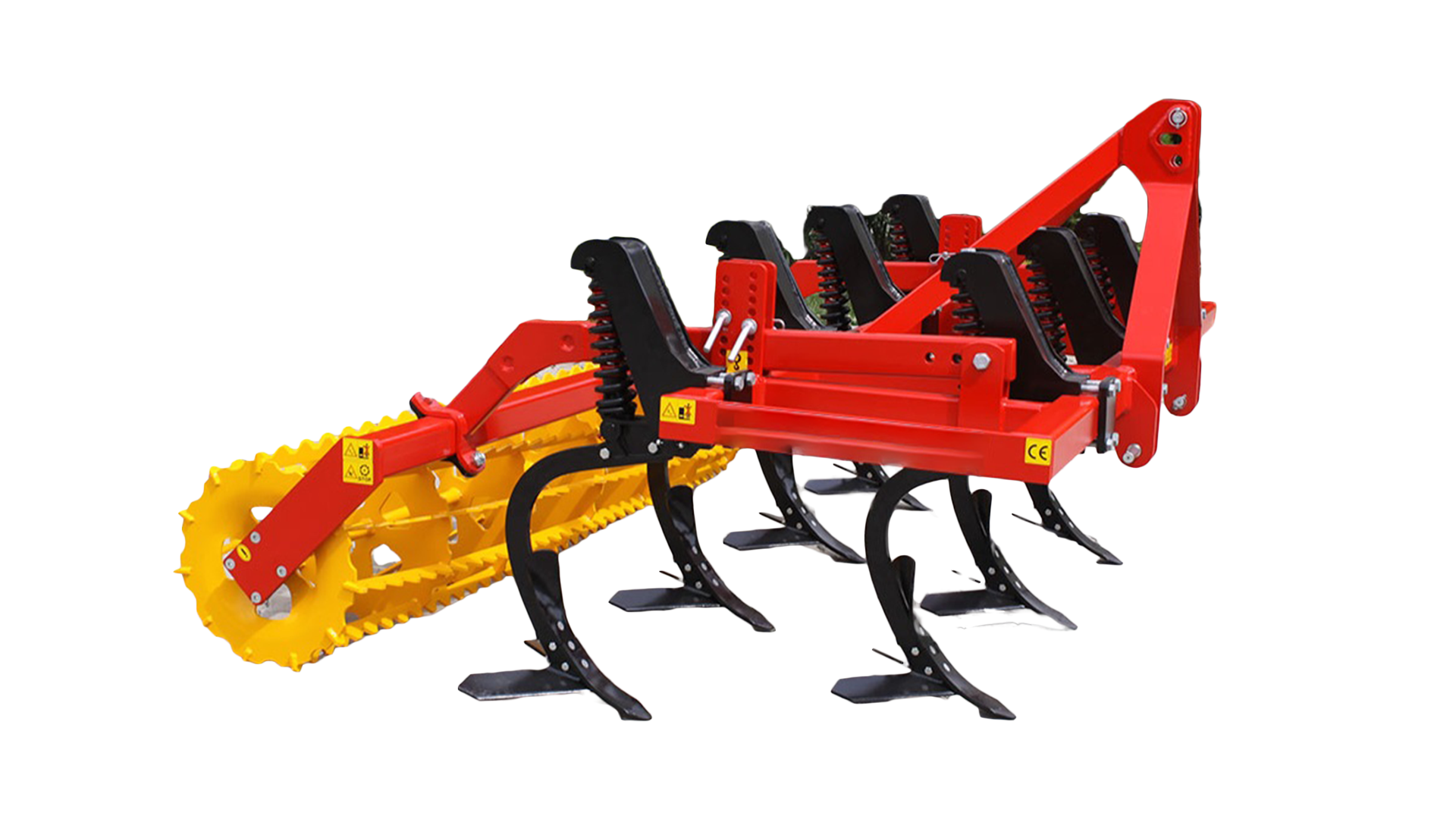

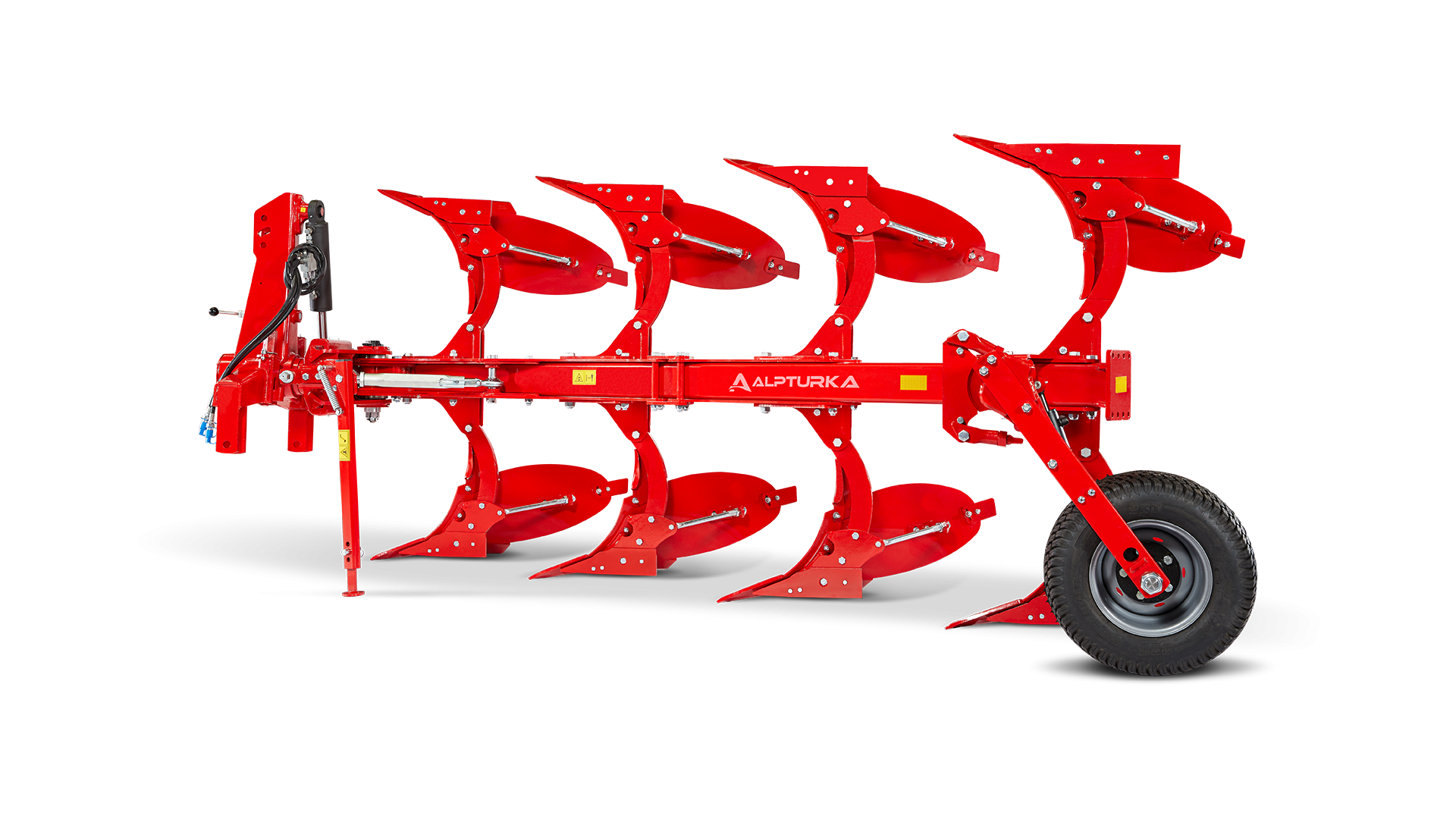

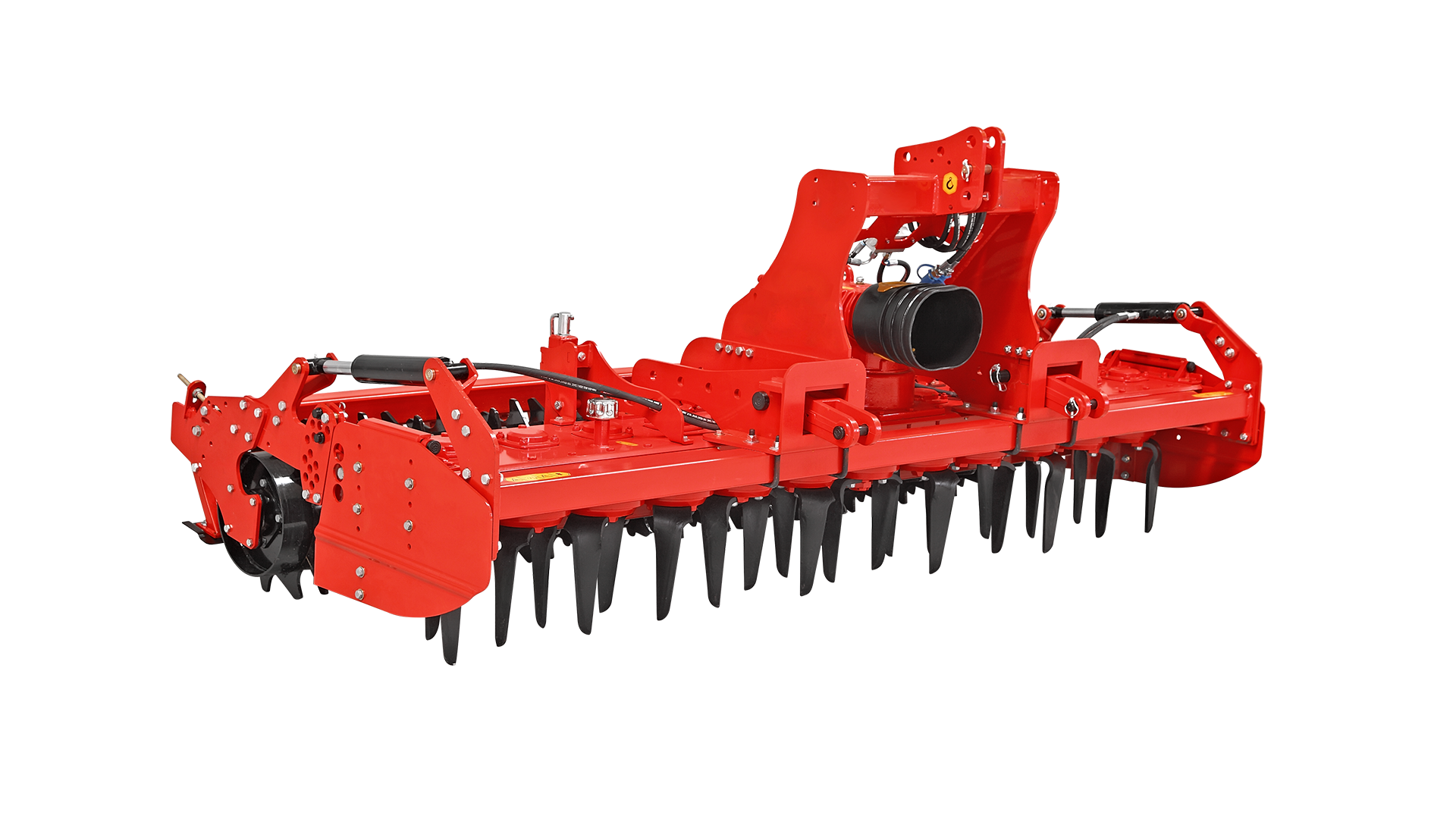

TUBULAR FRAME DISC PLOUGH

| TUBULAR FRAME DISC PLOUGH | ||||||||||

| MODEL NO | QUANTITY OF DISCS | TOTAL LENGTH | TOTAL WIDTH | DISC DIAMETER | BODY RANGE | WORKING WIDTH | WORKING DEPTH | HEIGHT | NEEDED POWER | WEIGHT |

| Pcs | mm | mm | cm | cm | cm | cm | cm | Hp | Kg | |

| PL-DT-2 | 2 | 1580 | 1180 | 66 | 53 | 66 | 25 | 125 | 40-45 | 297 |

| PL-DT-3 | 3 | 2040 | 1200 | 66 | 53 | 99 | 25 | 125 | 50-60 | 400 |

| PL-DT-4 | 4 | 2600 | 1550 | 66 | 53 | 132 | 25 | 125 | 60-70 | 484 |

| PL-DT-5 | 5 | 3010 | 1600 | 66 | 53 | 165 | 25 | 125 | 80-90 | 634 |

No catalog found for this product

No User Manual found for this product

Ploughs

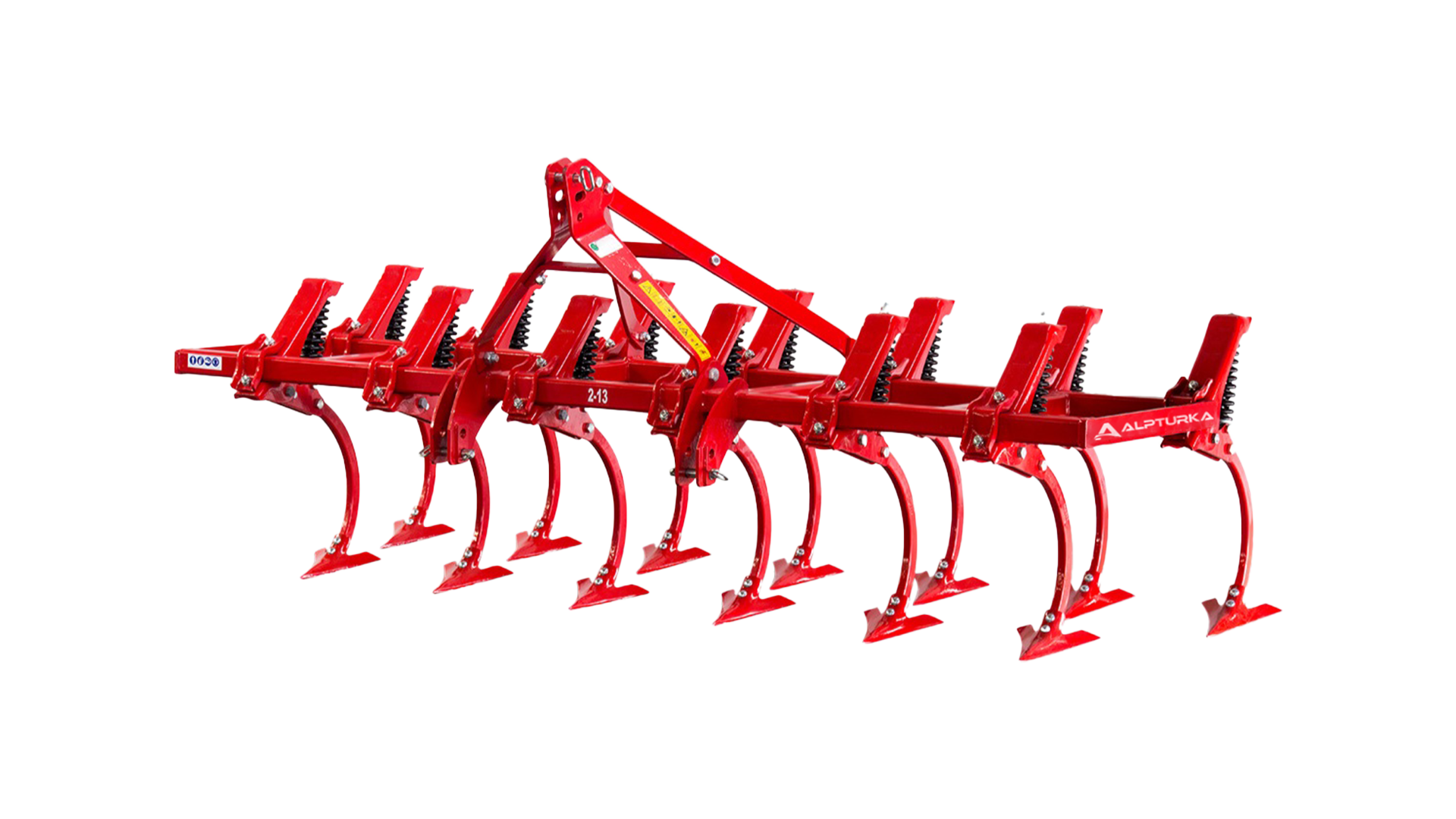

Ploughs Cultivator

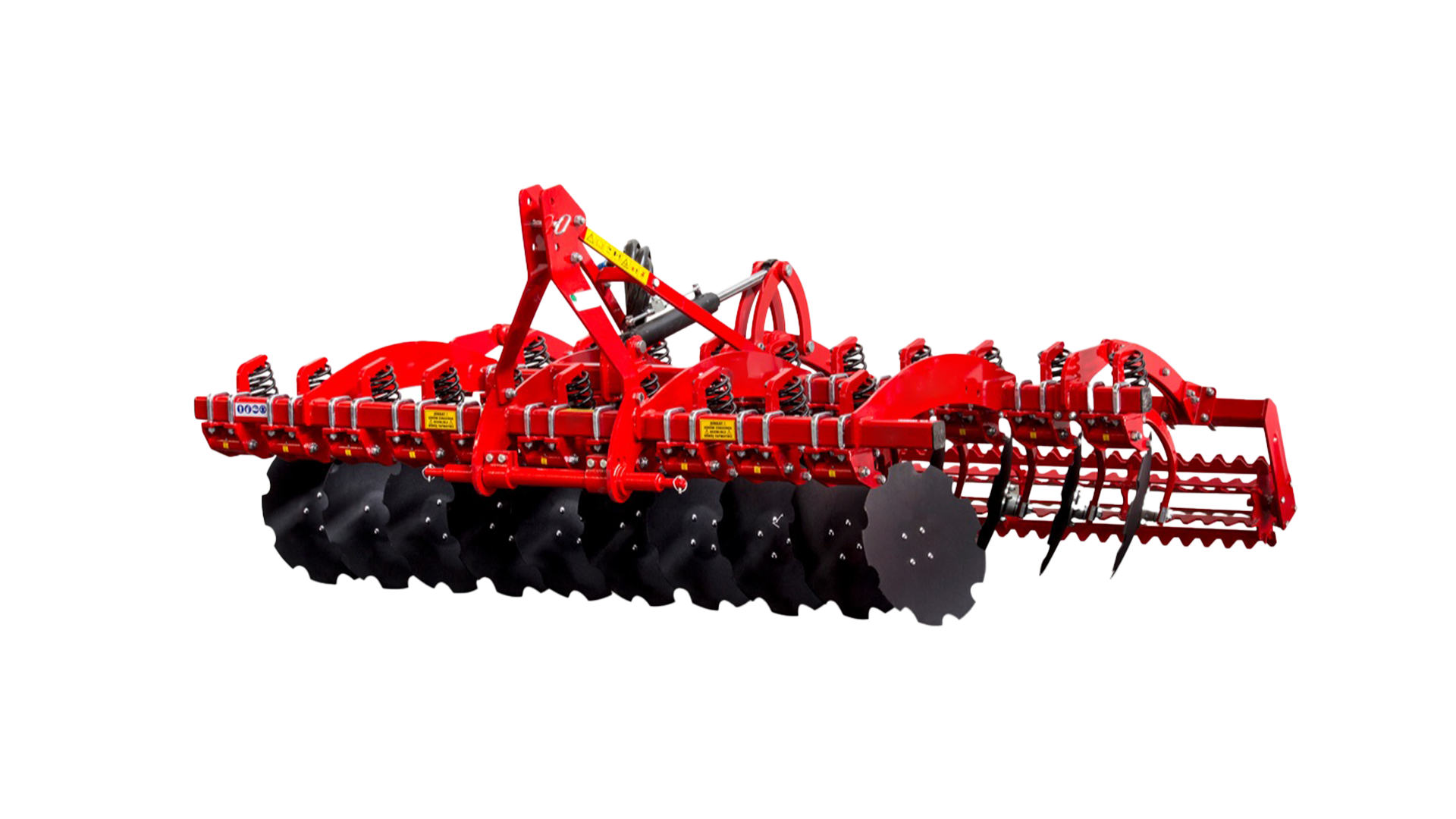

Cultivator Disc Harrow

Disc Harrow Chisel

Chisel Subsoiler

Subsoiler Interrow Cultivator

Interrow Cultivator Seedbed Preparation

Seedbed Preparation Land Leveler

Land Leveler Land Roller

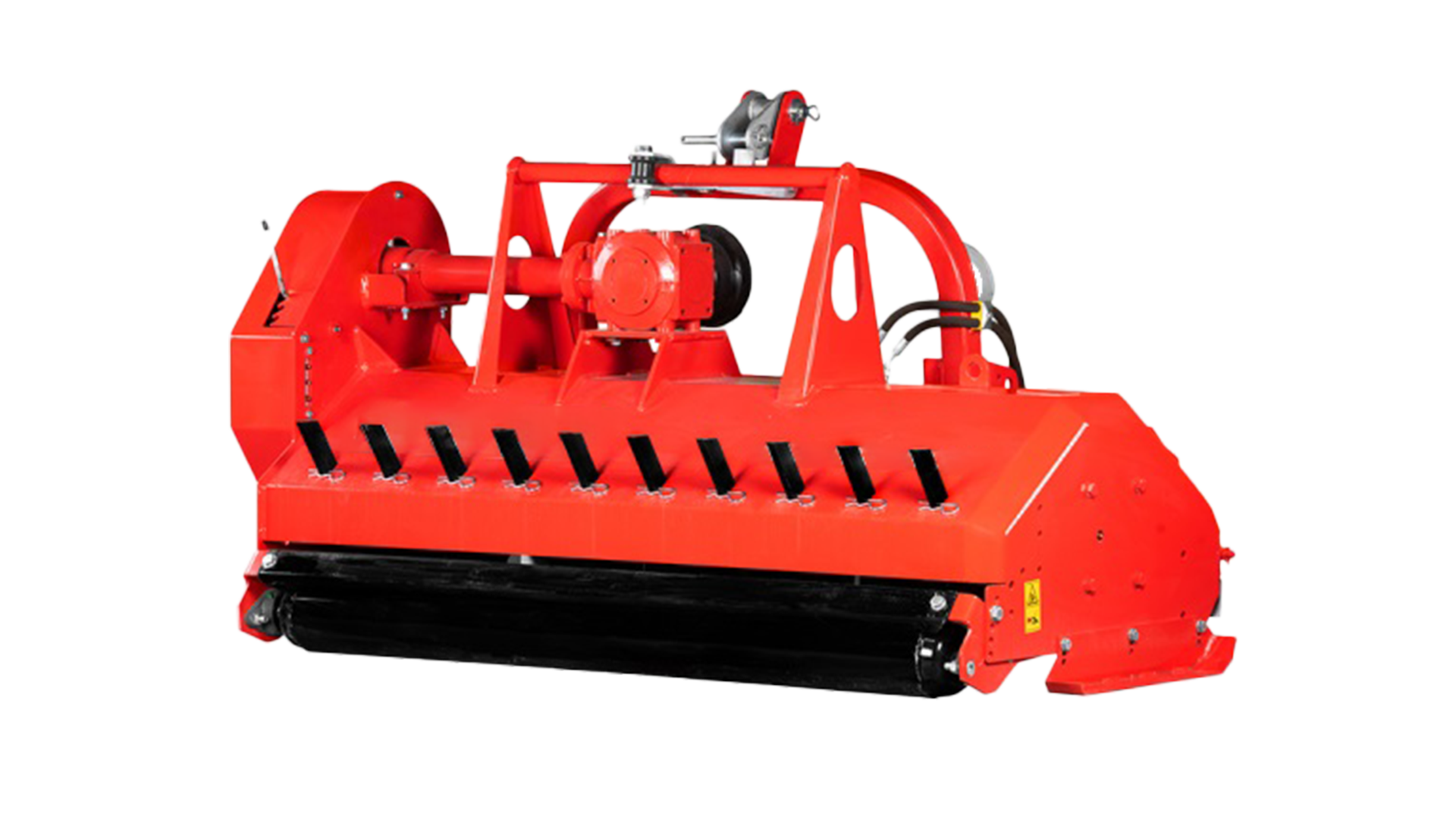

Land Roller Shredding & Mowing

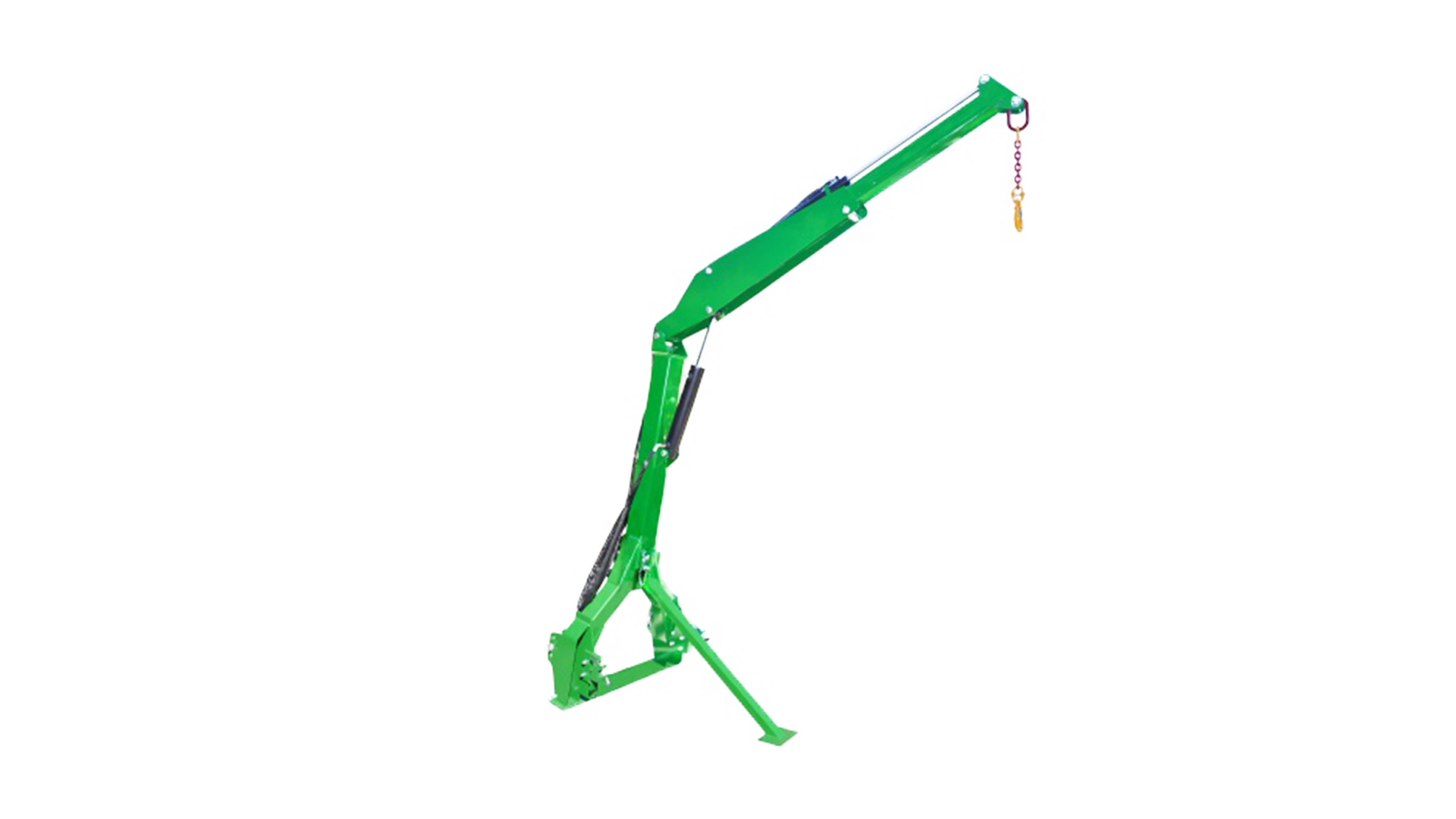

Shredding & Mowing Hole Digger

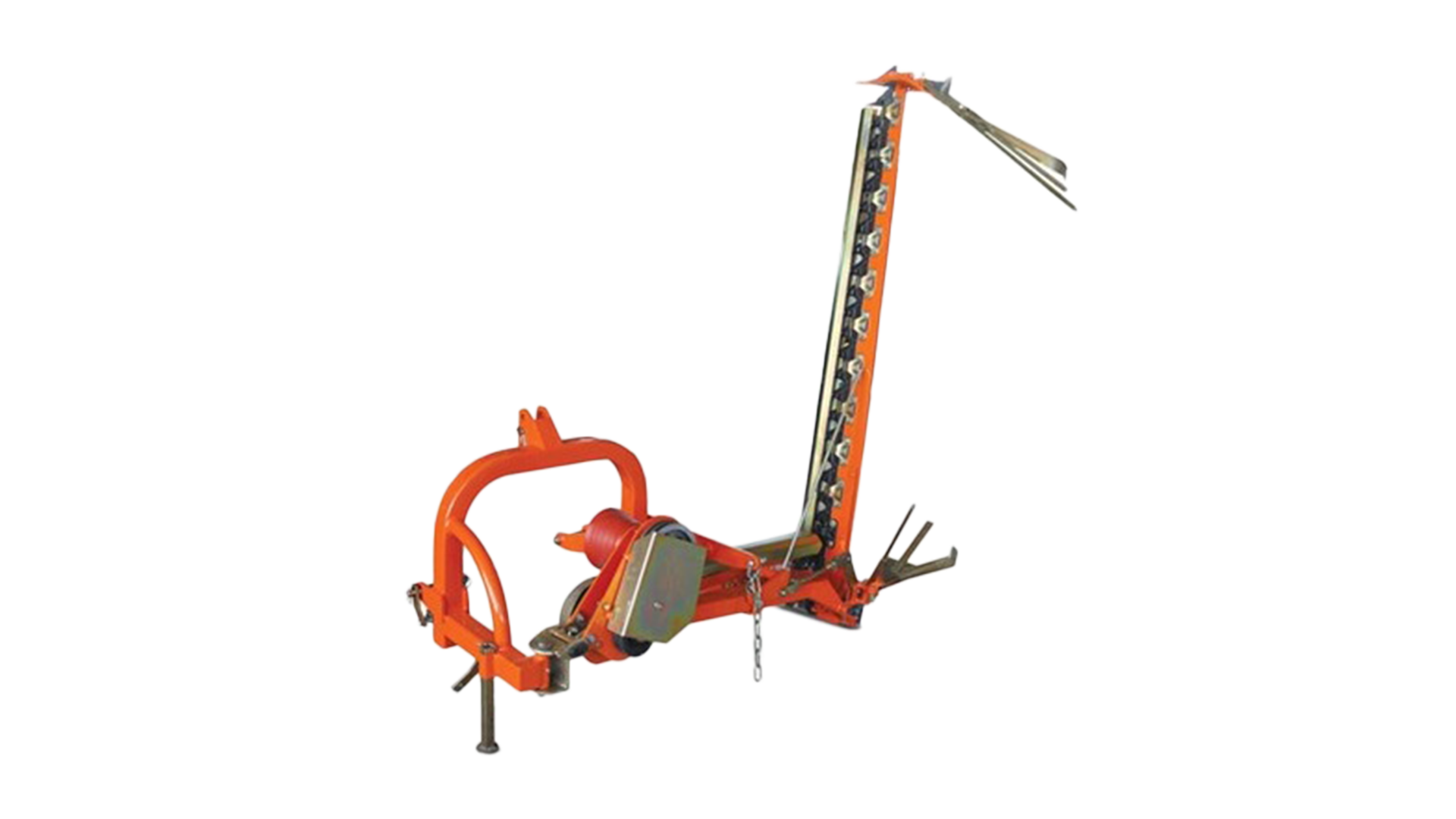

Hole Digger

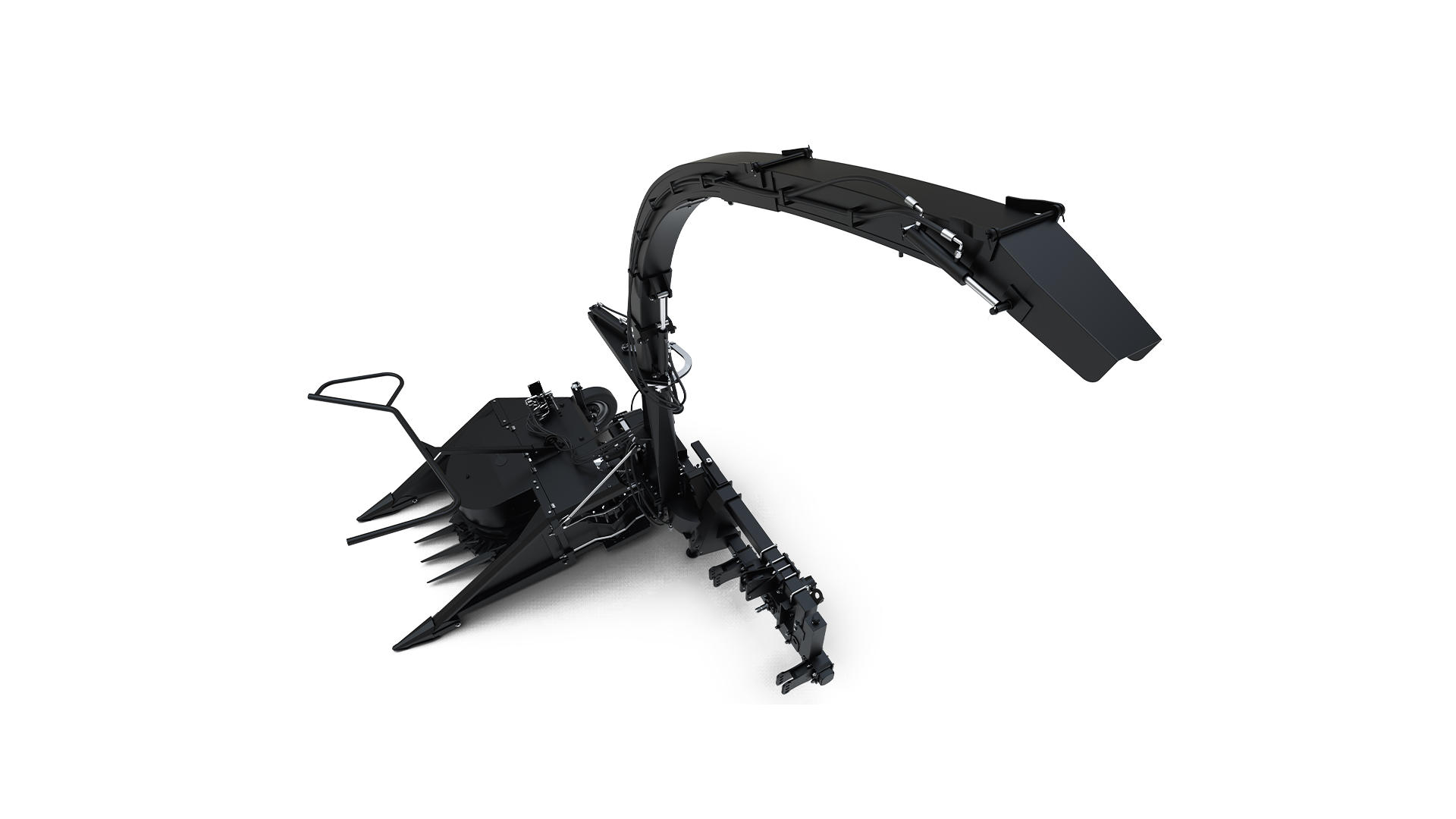

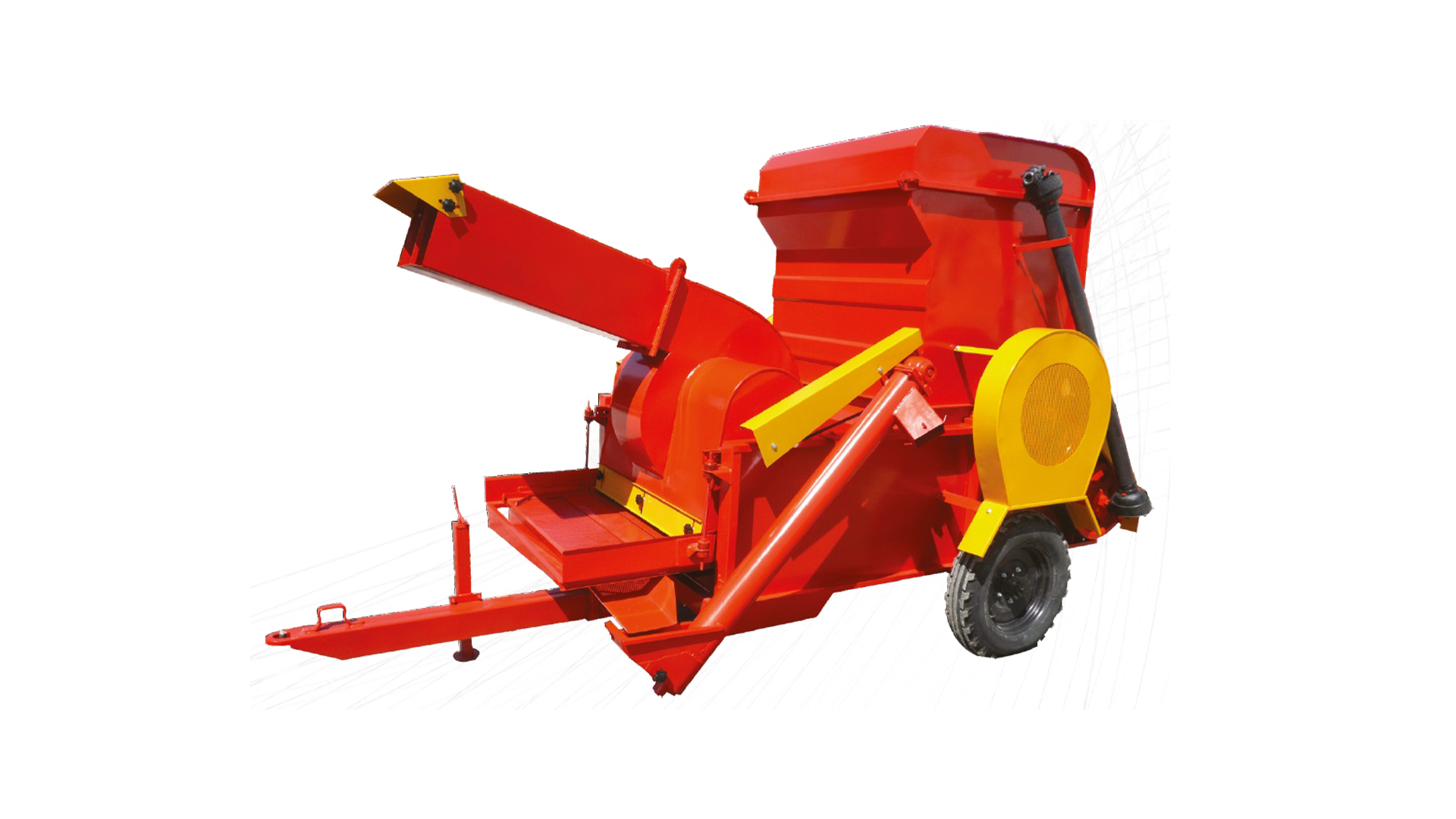

Silage

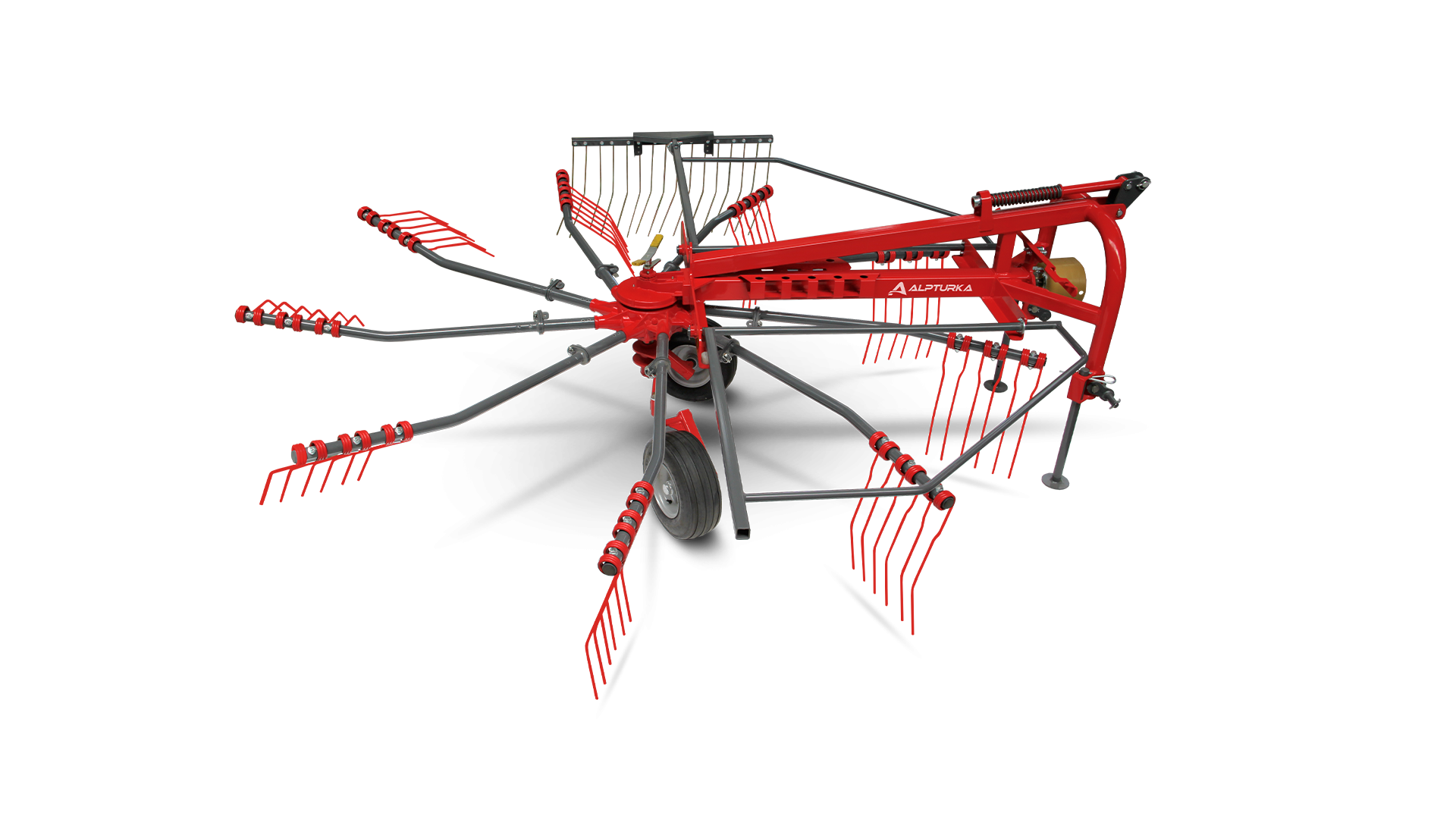

Silage Hay Making

Hay Making Baler

Baler Potato Harvester

Potato Harvester Thresher

Thresher

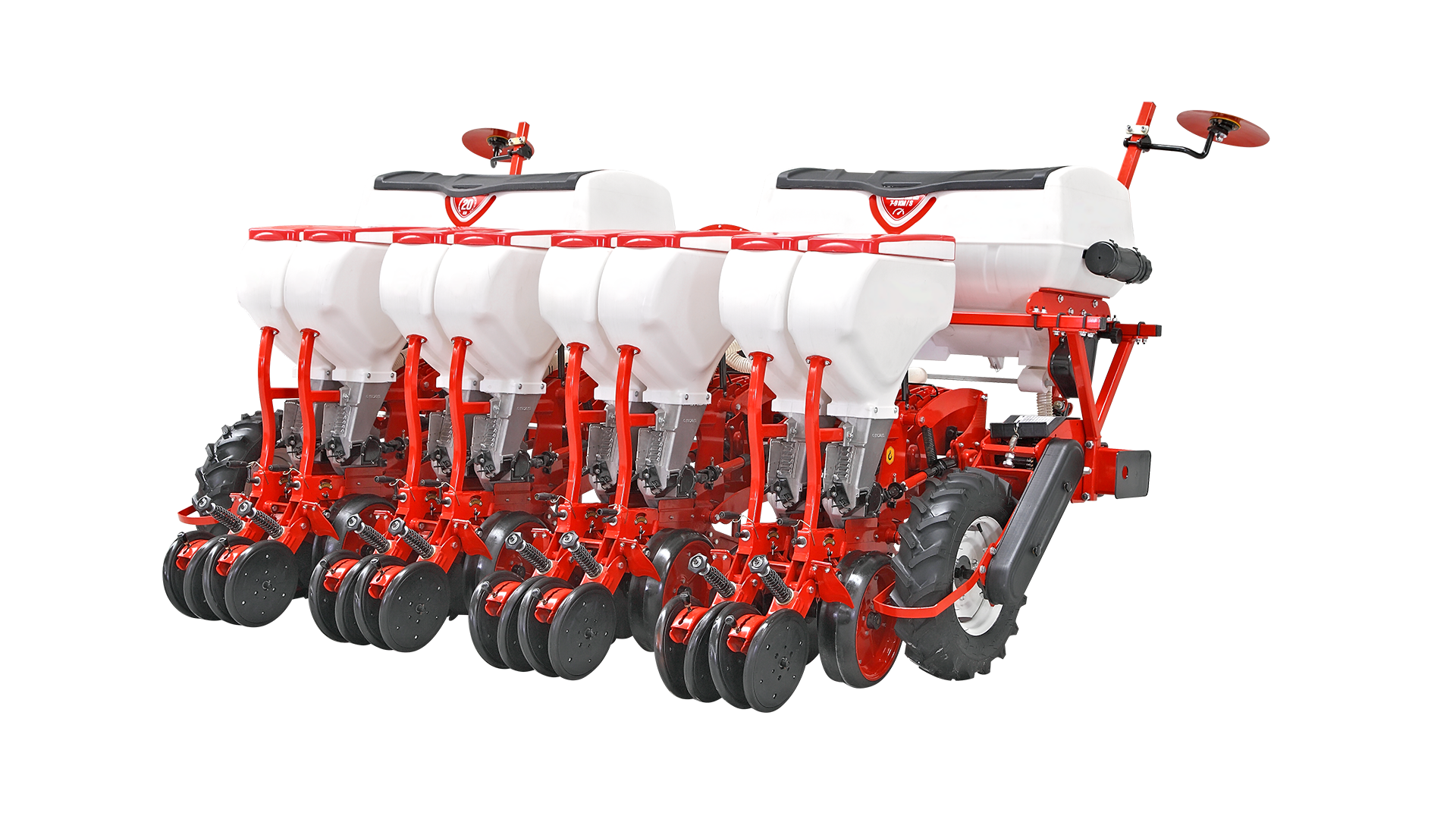

Pneumatic Planter

Pneumatic Planter Mechanical Seed Drills

Mechanical Seed Drills

Fertilizer Spreader

Fertilizer Spreader Manure Spreader

Manure Spreader Slurry Tanker

Slurry Tanker

Feed Mixer

Feed Mixer

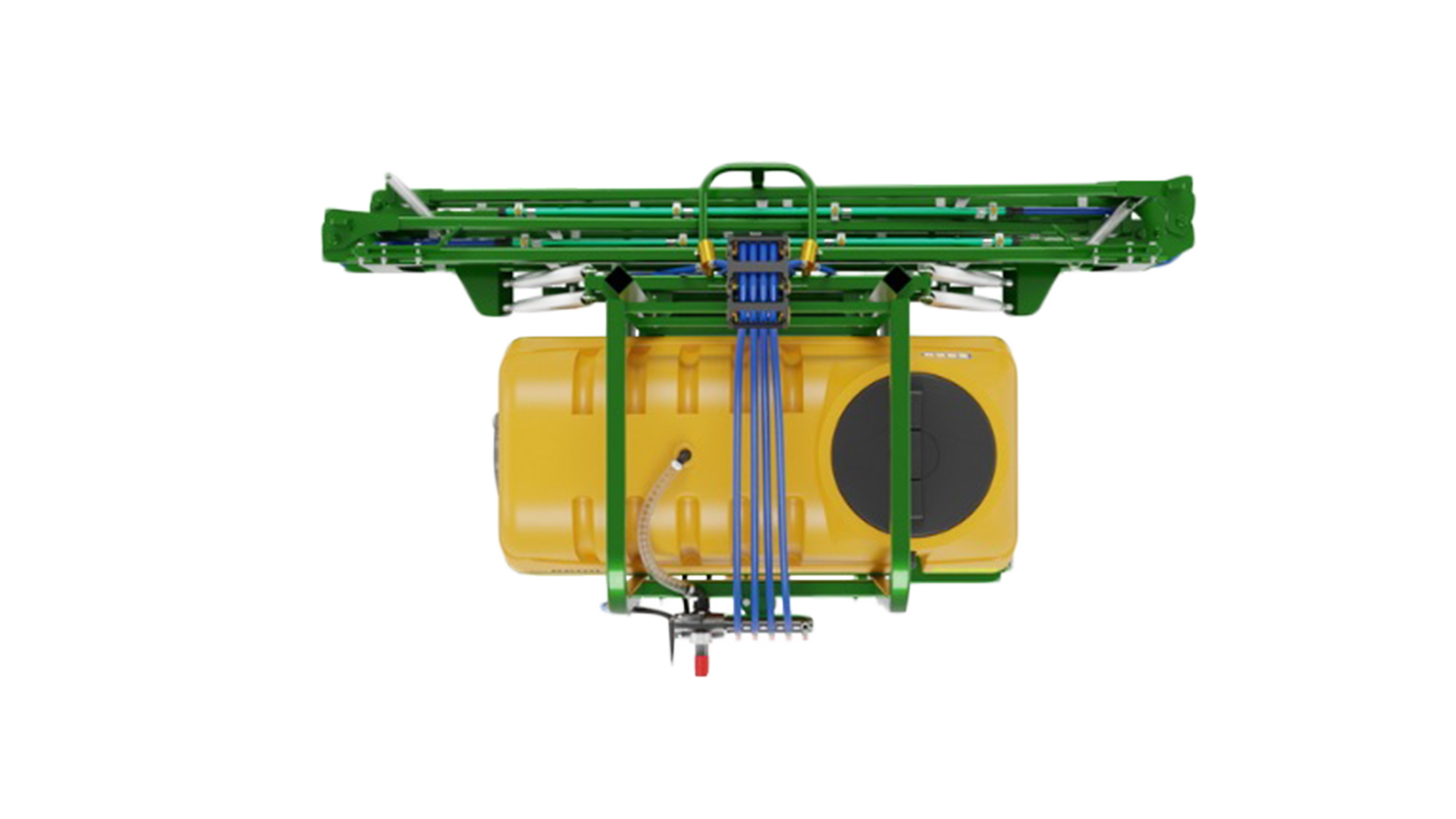

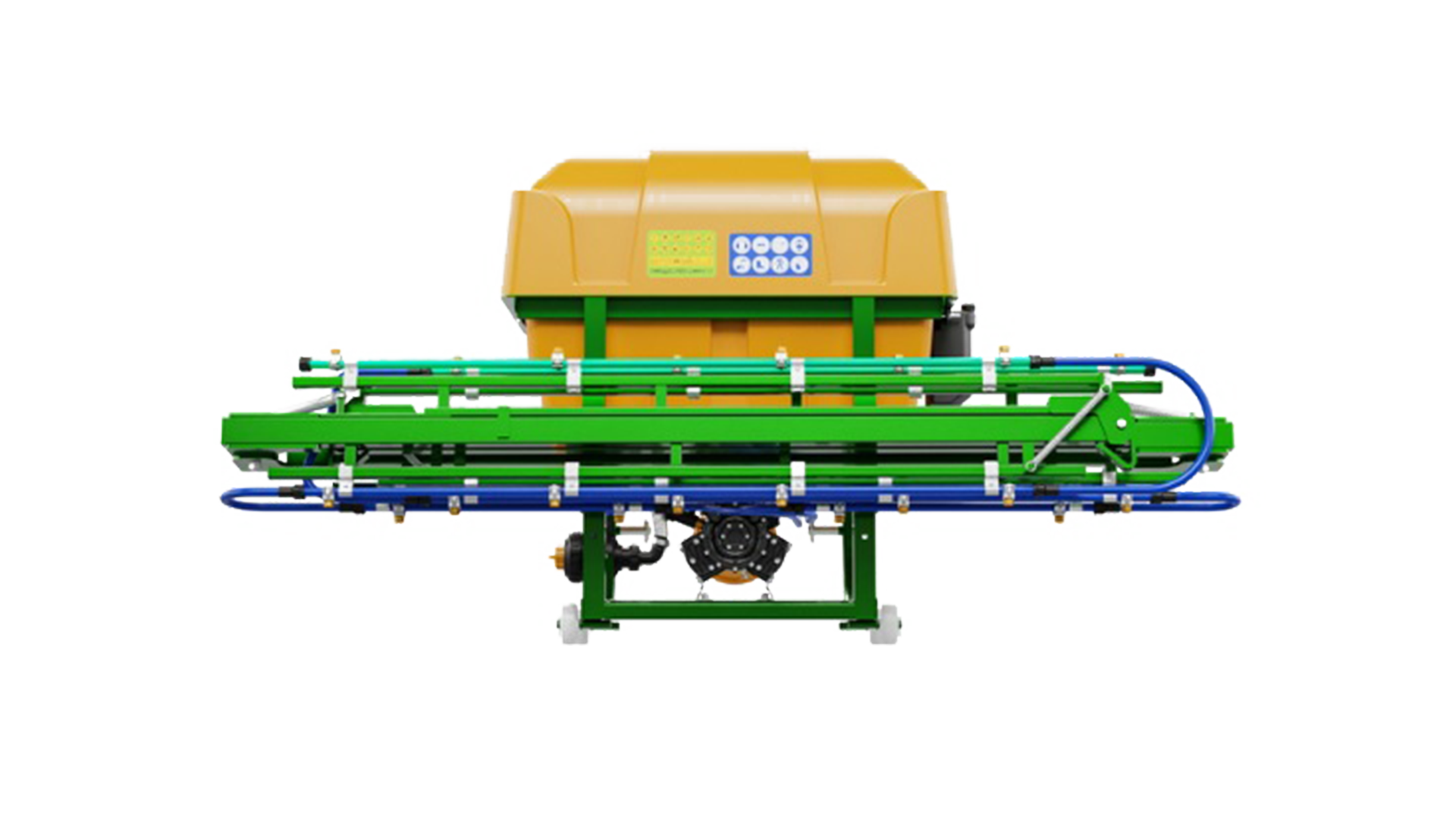

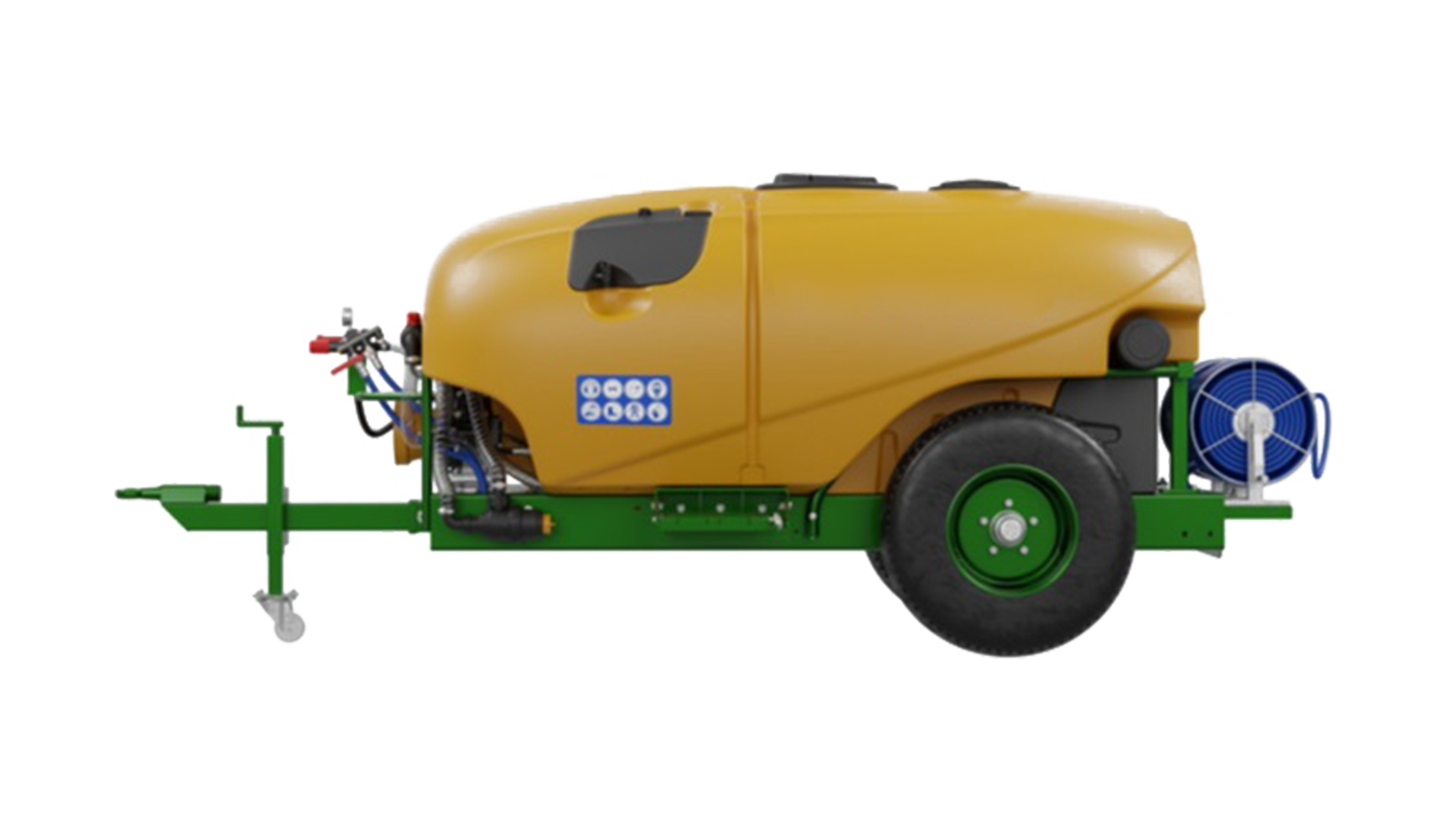

Field Sprayer

Field Sprayer Turbo Atomizer

Turbo Atomizer Garden Sprayer

Garden Sprayer Electrostatic Sprayer

Electrostatic Sprayer

Single Axle Trailer

Single Axle Trailer Double Axle Trailer

Double Axle Trailer Tandem Axle Trailer

Tandem Axle Trailer Triple Axle Trailer

Triple Axle Trailer Water Tank

Water Tank Baler Trailer

Baler Trailer Cotton Transport Trailer

Cotton Transport Trailer